CIVIL CONSTRUCTION CASE STUDY

JK Williams Left Point Solutions Behind and Reclaimed Hours Every Day with Simpel

Before Simpel: Balancing Point Solutions

Before adopting Simpel, JK Williams used a mix of point solutions: Procore for quality, Sine for site access, and hard copy forms for everything else. It worked, but as the business grew, so did the time spent chasing paperwork and switching between systems.

Jessica Gough

HSE Manager

Finding the Perfect Fit: The Evaluation Journey That Led to Simpel

The team had been exploring digital solutions for years but hadn’t found one that filled them with confidence—especially when it came to traceability and flexibility.

“We spent many years talking about what our systems would look like on a digital platform. The biggest thing was our work method statements and how we could prove someone had actually signed them.

A lot of systems just gave you a signature with no profile and no link to a person. You’d pass a tablet around and hope for the best. We had to take photo proof just in case. That’s why we stayed away from digital for so long. Nothing gave us the confidence that we could prove what we needed to. Then we saw Simpel and thought, ‘That meets all of our needs.’”

Having explored a slew of systems that didn’t quite deliver the full package, JK Williams approached Simpel with caution and a clear list of non-negotiables. The platform had to be practical, intuitive for site teams, and able to handle operational complexity without creating bottlenecks.

“We had our list of priorities, and we could see that Simpel aligned with them. We still didn’t jump in straight away—we’d been burnt before. But once we’d built our workflows and trialled them on our first project, we very quickly realised this was the right fit for us.”

Stopped Digging for Data: One View Into Every Project

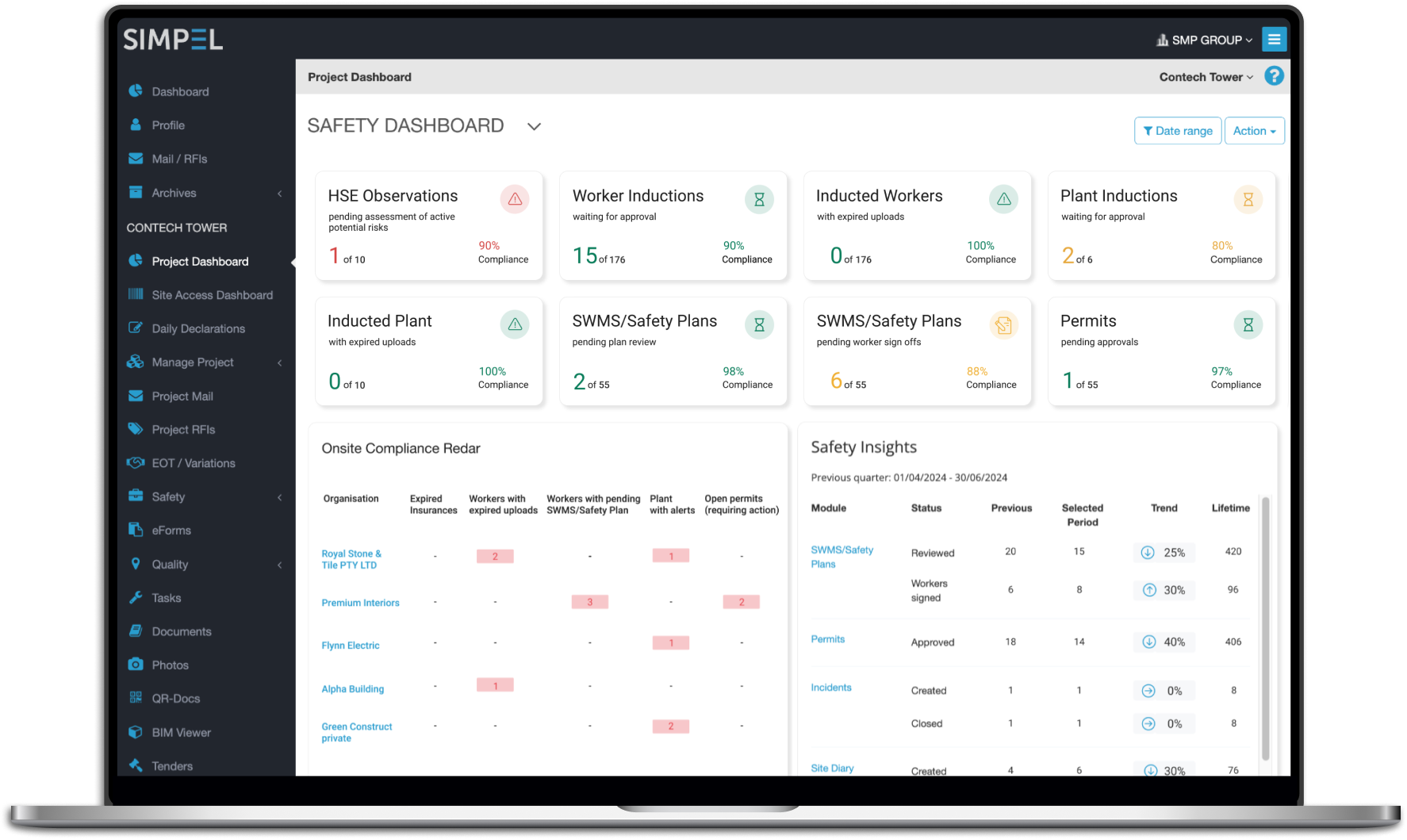

“The project dashboard really changed things, it was leaps and bounds for the team. I honestly think most of my supervisors just open that one module. They don’t have to go looking through the platform, it’s all just there. Once they saw how easy it was to find what they needed, they didn’t want to go back.”

Simpel’s Project Dashboards automatically surface the data that matters most. From overdue actions to attendance and sign-offs, project managers and leadership can quickly see what needs attention without clicking through folders or shuffling through filing cabinets.

They’re not just a static snapshot. The dashboards update in real time, giving teams up-to-date insight into daily compliance and emerging trends, without the legwork. They’re also fully interactive. Users can click straight into overdue actions or items that need attention and close them out.

Auditing Becomes Effortless When The Evidence Is Already There

Simpel has also made it easier for JK Williams to demonstrate full operational compliance workflows. Auditors no longer need to jump between tabs or even visit sites, to verify sign-ons, meeting minutes, or corrective actions. Everything is connected, with evidence linked back to the original form, incident, or register. That visibility has helped the business prove, at a glance, that nothing has been missed.

Live Access Anywhere, Anytime

When Simpel was first rolled out, JK Williams' auditor immediately noted the difference when they saw everything needed for review was live, linked, and right there in context.

“For our auditor, when we first introduced it, he loved it. He can be here in NSW, and I’ll go, ‘You want to check out the Queensland site? Here’s who’s checked in. They’re signed onto their SWMS. Let’s go.’ We just link everything up. Who’s on site today? Check. Their induction? Check. It’s all there. And we can do it all from our desktop.”

There’s no more requesting files or chasing records. With one login, auditors can validate and confirm that every process is being followed and closed out.

“In audit terms, it’s all about closing the loop. With Simpel, I can show the incident, the corrective action, the follow-up meeting, and the evidence—everything’s linked in one place. It’s a clear snapshot that shows we’ve done what we’re supposed to do.”

A Transparent Trail of Action and Accountability

Every part of the compliance process is now connected, and every gap is visible. If a signature is missing, if a meeting record hasn’t been logged, or if an action is still open, the system shows it.

“There’s no hiding. Like if you haven’t done something you were meant to do in the system, you can’t go backwards. It’s there, so we have to deal with it… which also protects all our supervisors because if they are doing their daily checks, if they are making sure this is occurring, that does nothing but help them. Everything is traceable, and that’s exactly what we need. We’ve had much more thorough audits because of it. They’re not just ticking boxes. They’re reviewing what’s happening and actively reducing risks.”

Every step tracked. Every action linked.

Shaping Expectations, Not Just Meeting Them: A Platform That Earns Client Confidence

Since partnering with Simpel, JK Williams have done more than meet client requirements—they’ve positioned themselves to lead conversations around digital capability, audit readiness, and delivery assurance. With a structured, traceable, and auditable system purpose-built from the ground up, there’s no need to retrofit during procurement. A concept they’re advocating for with their own clients.

“Being able to sit there when you’re tendering and say to a client, ‘Hey, we can give you complete oversight of ITPs, live and as they unfold’ — that’s a huge win.”

For Jessica, that visibility isn’t just a feature, it’s a differentiator. When clients see Simpel in action, their expectations shift.

“When we talk to clients and walk them through the system, their whole view changes. They love that they can peek behind the curtain and see what's happening on site.”

That shift has gone further than interest. For some, it’s becoming a line item in procurement.

“We’ve had another client talk about potentially even adding it as either people tendering on the project must have Simpel or something of the equivalent value. And I’m like, well, nothing’s equivalent. Nothing matches this. So, you should just say people have to have Simpel.”

What started as a tool to improve internal operations has become a competitive edge—giving JK Williams the confidence to lead, the capability to deliver, and the opportunity to meet tender requirements before they’re even written.

The Power of Easy-to-Use Software: From Zero Digital Exposure to Fully Mobile Sites

Introducing new tech is one thing. Bringing an entire team from paper-only processes to full digital operations is another. While JK Williams’ NSW staff had some experience with digital systems, JK Williams Queensland branch (formerly DAC) hadn’t used digital platforms at all.

“Queensland had only ever written on paper. Nothing was digital. They didn’t even really know digital programs like this existed. So, when we went from minimal paperwork to full digital compliance, and they were happy to do it because they could see how much easier it made things.”

The shift could have been a major challenge, but it wasn’t. By showing how digital workflows would make their day easier, the team got on board quickly.

“We said, ‘You’re not going to need folders anymore. You’ll be able to stand in the back paddock and open drawings, forms, whatever you need, on your iPad.’ That’s what helped get them on board.”

Redbank Southern Valley

For site teams used to handling forms manually, the ability to pull up drawings, sign-ons, and checklists in the field made a great impression. Even those hesitant to make the leap quickly saw the value.

“We had some of the older guys whose emails were still shared with their wives. Tech just wasn’t part of their daily routine. But once we trained them up and they saw everything was just there, they got it. It didn’t take long before they preferred it over the old way.”

About JK Williams

JK Williams is a family business founded over 65 years ago built on a solid reputation for market distinction; it has a rich family history together with a strong heritage of quality, stability and innovative leadership.

The dark blue background and bright yellow lettering of JK Williams is instantly recognisable on the extensive and modern fleet of civil construction and transport equipment. The company, rich in tradition, and proud of reputation, is a highly respected corporate citizen of the Western Sydney area renowned for delivering innovative solutions in the civil construction sector.

How much time do you spend on repetitive admin?

See how Simpel can help you save hours every day with a unified approach to operations